Why cell type (cascaded H-bridge) technology is better than other technologies?

The cell type (cascaded H-bridge) technology has some unique advantages over other technologies.

For example, this technology uses phase shifted multi-secondary transformer at the input to provide isolated power source to each power cell. This provides 18-pulse performance for 3.3 kV, 24-pulse for 4.16 kV, 36-pulse for 6.6 kV and 54-pulse performance for 11 kV system and reduces the input total harmonic distortion to a great level.

The power factor offered is better than 0.95

It uses low voltage components like IGBT, Diode and Capacitor, which are widely used and extremely reliable, easy to procure with lesser lead time.

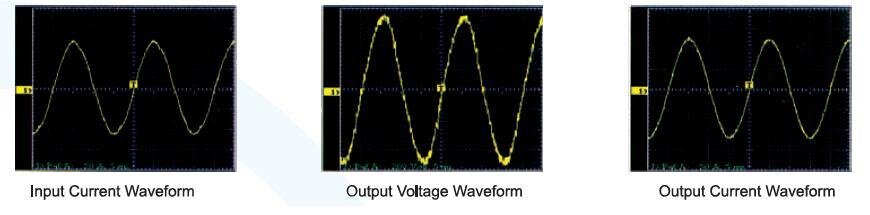

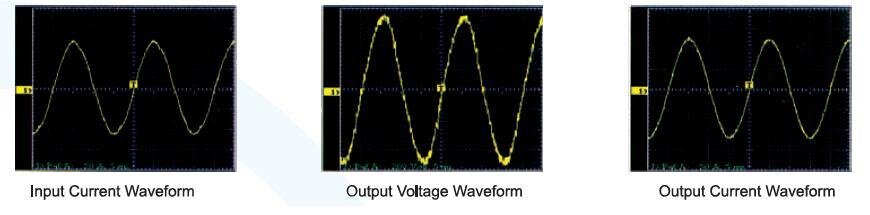

The output voltage waveform are overlapped PWM with the voltage levels of 7 per phase in 3.3 kV, 9 in 4.16 kV, 13 in 6.6 kV and 19 in 11 kV system. This result in great reduction in output harmonic content and the output voltage waveform is nearly sine wave. It means,

- No output filter required

- Can drive normal high-voltage motor without increasing the motor temperature or decreasing the motor capacity, no special motor required.

- No restriction on cable length

- No damage to motor insulation due to dv/dt stress

Can I use Axpert-Hivert series Medium Voltage Drive with the existing motor?

Yes, one can use Axpert-Hivert Series Medium Voltage Drive with existing motor without derating. This is possible due to nearly sinusoidal output voltage waveform.

Why reliability of Axpert-Hivert Series Medium Voltage Drive is good?

Axpert-Hivert series Medium Voltage Drive uses field proven, highly reliable low voltage components like Diode, IGBT and Capacitors. This ensures highest reliability of the Medium Voltage Drive.

Which are common voltage levels offered?

The most common voltages are 3 kV, 3.3 kV, 4.16 kV, 6 kV, 6.6 kV, 10 kV, 11 kV

Which are the application areas of Axpert-Hivert Series Medium Voltage Drive?

The Axpert-Hivert Series Medium Voltage Drive can be successfully used in various applications like:

- Thermal power, Hydro power, Garbage biomass

- Petroleum, Petrochemical, Natural gas

- Coal mines & minerals

- Steel & nonferrous metallurgy

- Cement & building materials

- Municipal (heat supply, water supply, sewage etc.)

- Light Industry, Chemical Industry

- Military industry & others

Which are the application areas of Axpert-Hivert Series Medium Voltage Drive?

The Axpert-Hivert Series Medium Voltage Drive can be successfully used in various applications like:

- Thermal power, Hydro power, Garbage biomass

- Petroleum, Petrochemical, Natural gas

- Coal mines & minerals

- Steel & nonferrous metallurgy

- Cement & building materials

- Municipal (heat supply, water supply, sewage etc.)

- Light Industry, Chemical Industry

- Military industry & others

Which are different topology / technologies exist for Medium Voltage Drive.

The Medium Voltage Drive can be broadly divided in to,

- 1. Current Source Inverter

- 2. Voltage Source Inverters

The voltage source inverters can further be divided in to,

- Two-Level Inverter

- Neutral Point Clamped Inverter

- Multi-level Cascaded H-bridge Inverter (cell type)

- Multi-level Flying capacitor Inverter

- Multi cell technology uses multi-level inverters using multi-secondary transformers. Each cell in multi cell medium voltage drive uses H-bridge inverter.

- When you want to save power coming from regenerative loads then you should use Regenerative type Multi cell Drive.

What are the control options available?

The Axpert-Hivert Series Medium Voltage Drive can be controlled from three places as below.

- Local Control: Direct control from the button on cabinet door or touch screen HMI. This is the main control method.

- Remote I/O Control: Realize remote control by connecting to the remote switch signal via the I/O board.

- Host Control: Isolated RS-485 port and adoption of standard MODBUS-RTU communication protocol. Able to connect with host system like DCS for optimized coordination control.

How many options user has for frequency setting?

The user can set the frequency from any of the below source.

- Direct command from main interface (Touch screen HMI)

- Set by analog signal (4...20 mA)

- Set by host computer via RS-485 port

- Multi-speed set, suitable for the working conditions in cyclic change

- In the event of closed-loop operation, it will be automatic set by built-in PID for the process parameter control like flow, pressure etc…

What is the PID Function?

Built-in full digital PID is provided for closed-loop control upon the users' requirements to control the process parameters like pressure or flow. The PID parameters can be adjusted online.

How many Digital input and output available in Axpert-Hivert Series Medium Voltage Drive?

Axpert-Hivert series Medium Voltage Drive offers 14 digital inputs and 22 digital outputs.

What is the overload capacity offered by Axpert-Hivert Series Medium Voltage Drive?

The Axpert-Hivert Series Medium Voltage Drive offers 120 % overload capability for 120 Seconds.

What is the Operating environmental temperature of Axpert-Hivert Series Medium Voltage Drive?

The Axpert-Hivert Series Medium Voltage Drive can be successfully operated from 0...45 °C. Please note that providing clean and dust free operation is extremely necessary for the trouble free operation of Medium Voltage Drive.

For critical applications, what is the solution if Medium Voltage Drive trips or fails?

The Axpert-Hivert Series Medium Voltage Drive is extremely reliable. But still if user wants, we optionally offer either manual bypass function or automatic bypass function to switch over the operation to bypass in case Medium Voltage Drive trips or fails.

How can I rely on Amtech for highest up time for Medium Voltage Drive applications?

Amtech is one of the leading manufacturers of AC Drive with world class manufacturing facility and strong in-house R&D. Amtech has come up with the state-of-art technology innovated Axpert-Hivert Series Medium Voltage Drive. Today, Amtech is in a position to provide highest up time in the industry with the strong technical support system and global network.

What is Automation?

Automation products such as PLC’s, SCADA system HMI/MMI units, servo/stepper drives are required for machine automation, line automation, plant automation and process automation.

What are Industrial control equipment/Industrial electronics?

Industrial control equipment/industrial electronics include product such as high voltage DC power supply, special power supplies required by research organizations, Pulse widh modulated (PWM) DC drives for traction applications, solar inverter, wind power converters and so on.